Contact: Manager Ni

Telephone: 13773289099

Address: Building 9, Dehao Manufacturing Valley, Lekun Road, Zhangjiagang City, Jiangsu Province

With high-quality products, professional services, and systematic support, Xinyizhong helps the construction of modern factories in the filling industry,

to grow together with customers, and make the development of the enterprise go farther and longer.

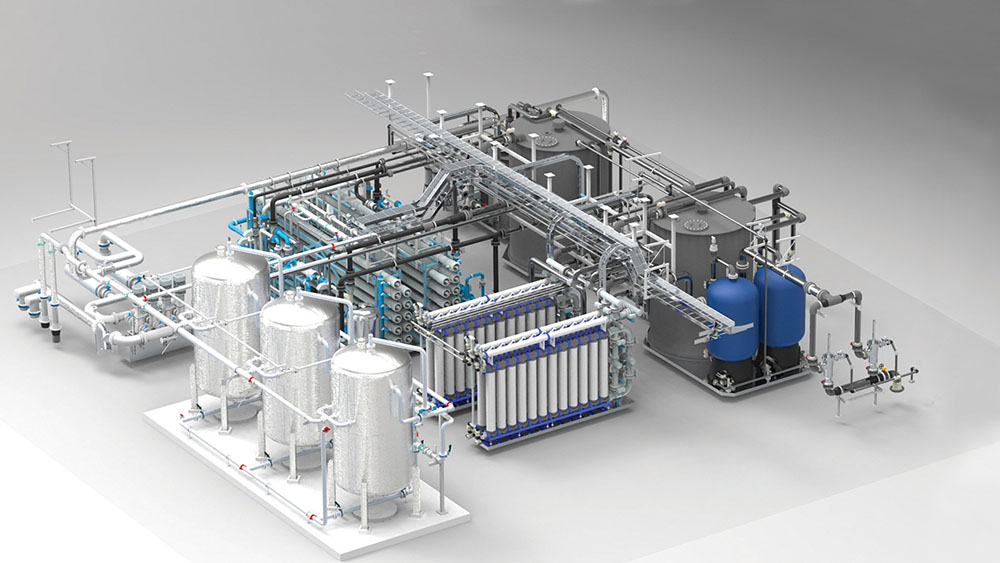

This series of commercial and industrial reverse osmosis systems are engineered to economically produce high purity water by removal of dissolved minerals, bacteria, particles, and organic impurities. Each machine is constructed using the highest quality components and materials for reliable operation and exceptional performance. Product water capacity is 5000 liters per hour. Standard machine comes with pre-treatment including sand filter for removal of suspended solids and turbidity, activated carbon filter providing cost effective removal of chlorine, chloramines, and/or organics that can cause taste, odor, or color in water, dosing pump by which an antiscalant solution should be dosed before the reverse osmosis membranes to disperse calcium carbonate and sulfates precipitates in order to avoid scaling, a 5mirco cartridge filter prior to the high pressure pump serve as the final barrier to water born particles and reverse osmosis system which is a process in which dissolved inorganic solids (such as salts) are removed from a solution (such as water). This is accomplished by pressure of high pressure pump pushing the water through a semi permeable membrane. The membrane which is about as thick as cellophane allows only the water to pass through, not the impurities or contaminates. These impurities and contaminates are flushed down the drain.

Technical route and flow diagram instructions

Raw water tank → Booster pump → Sand filter → Activated carbon filter → Softener Micro filter→ High pressure pump → Reverse osmosis → Permeate tank

Key Features

Materials of Construction

Skid Frame: SS304

Membrane Elements:Hydraulics ESPA2-4040

Membrane Housings: SS304

Low pressure piping: SS304

High pressure piping: SS304

Pump and Motor

Pump: 304SS vertical multi-stage centrifugal

Motor: TEFC, 380/460 VAC, 3-phase, 50/60 Hz.

Standard Features

4” x 40” High rejection membrane elements

5-micron sediment pre-filter housing

Automatic inlet solenoid valve

PLC control

Product water conductivity monitor

Operating pressure gauges

Product and concentrate flow meters

Concentrate and recycle flow control valves

Low inlet pressure switch with shutdown alarm

Auto/Manual wash

Optional Equipment Available

Atmospheric storage tanks with level control and repressurization pump

Pressurized storage vessels

UV

Ozone generator

Membrane clean-in-place (CIP) systems

Pretreatment chemical injection systems

Technical Specifications

Model No | WT-RO-XYZ |

Capacity | 5000LPH(Liter per Hour) |

Nominal Recovery | 65-75% |

Nominal Salt Rejection | 99.60% |

Operating Temperature | 15°C-45°C |

Design Temperature | 25°C |

Feed Pump | 1.1KW |

High Pressure Pump | 5.5KW |

Voltage | 220V /380V/460V – 50Hz/60Hz |

Specifications are subject to change without notice, All rights are reserved.