Contact: Manager Ni

Telephone: 13773289099

Address: Building 9, Dehao Manufacturing Valley, Lekun Road, Zhangjiagang City, Jiangsu Province

With high-quality products, professional services, and systematic support, Xinyizhong helps the construction of modern factories in the filling industry,

to grow together with customers, and make the development of the enterprise go farther and longer.

Semi Automatic Shrink Wrapping Machine

Semi automatic/manual bottle shrink wrapping machine is designed for small operations and startup companies, low cost, easy to use and widely used to wrap a wide variety of packs either as individual packs(e.g.,carton) or as collations(e.g.,bottles,cans,jars,boxes,etc.) into their respective formats (either 4 bottles x 6 bottles(1/2 liter) or in other packaging configurations such as the 3 x 4, 1-liter arrangement to be wrapped unsupported, pad-supported or tray-supported. Each shrink wrapping system comes with bundler, shrink tunnel and discharge conveyor.

With a semi automatic/manual shrink wrapping machine for bottles, The products are positioned in the front of the pneumatic infeed pusher by hand, a button is pressed which starts the wrapping cycle, the collated product is then pushed to sealing and cutting station by air cylinder. Shrink wrapper machine commonly use two reels of film which are joined to form a web, one reel is mounted at high level and the other is mounted at a low level. The product to be wrapped is passed through the web. The sealing bar descends to seal and cut the film to form an envelope around the package leaving two open ends at the sides.

After sealing, the next product to be wrapped then pushes the wrapped product into the heat shrink tunnel where recirculated hot air causes the wrapped products to shrink and tightly confirm to the contours of the contents. Once the pack is out of the chamber, forced air cooling is used to tighten the sleeve wrap to achieve a strong, secure pack ready for stacking on a pallet or placing in a shipping carton.

Sleeve Wrapper Features

Heavy duty frame construction made on painted steel tube

Wheels and height adjustable legs for transport and positioning

Flexibility to wrap trayed and trayless packs

Accepts a package size of 500mm(W) X 350mm(H)

Adjustable pusher assembly with two hand start switches

Adjustable product hold down device to press containers of different height

Adjustable product clamp and dead plate for containers of different diameter

Convenient controls for easy set up

600mm flat maximum shrink film width

Unique heavy duty specially profiled sealing jaw for consistently strong seals

Teflon coated sealing blade

Top and bottom powered film unwind

Easy to use and maintain

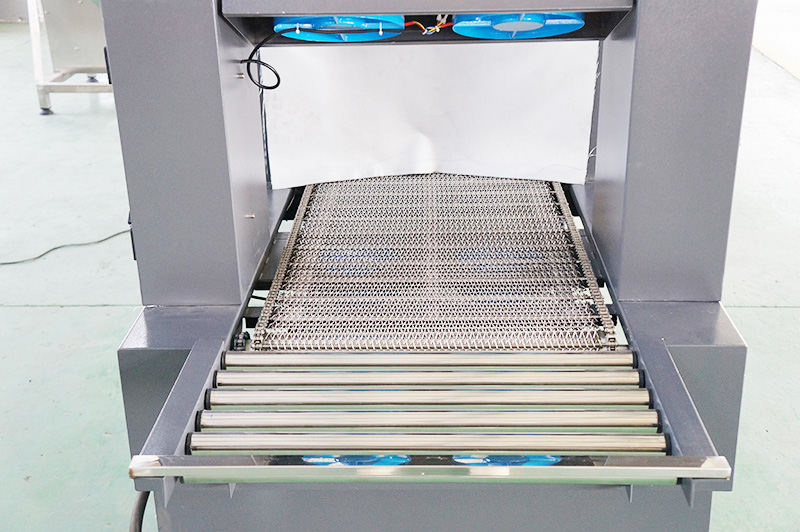

Shrink Tunnel Features

Heavy duty welded steel frame with adjustable height

Wheels and height adjustable legs for transport and positioning

Insulated shrink tunnel chamber

Stainless steel heating elements for long life

Shrink tunnel opening is 550cm(W) X 400mm(H)

Adjustable conveyor speed

Adjustable temperature control

Dual blower design with adjustable air flow

Durable and non-stick teflon mesh conveyor belt

Tunnel discharge cooling station for fast film curing

Discharging idle roller conveyor for accumulation and easy transportation

Packing Speed | 5-8Packs/Min |

Max Pack Size | 500(W)x350(H)mm |

Applicable Film | Polyethylene(PE) Film |

Max Film Thickness | 100Micro |

Shrink Wrapper | |

Max Film Width | 600mm |

Sleeve Wrapper Electric Supply | 220V 50/60HZ 1PH 1.50KW |

Top Film Feeding Motor | 220V 50/60HZ 1PH 25W |

Bottom Film Feeding Motor | 220V 50/60HZ 1PH 25W |

Sleeve Wrapper Dimension | 1040x930x1930mm |

Sleeve Wrapper Weight | 200kgs |

Shrink Tunnel | |

Shrink Tunnel Opening | 550mm(W)x400mm(H) |

Shrink Tunnel Heater | 380V 50/60HZ 3PH 18.40KW |

Conveyor Motor | 220V 50/60HZ 1PH 90W |

Reciriculation Blower | 220V 50/60HZ 1PH 120W(60Wx2) |

Shrink Tunnel Chamber | 1500x550x400mm |

Shrink Tunnel Dimension | 2500x800x1480mm |

Shrink Tunnel Weight | 360kgs |

Idle Roller Conveyor | |

Dimension | 1200x550x720mm |

Idle Roller Weight | 60kgs |