Contact: Manager Ni

Telephone: 13773289099

Address: Building 9, Dehao Manufacturing Valley, Lekun Road, Zhangjiagang City, Jiangsu Province

With high-quality products, professional services, and systematic support, Xinyizhong helps the construction of modern factories in the filling industry,

to grow together with customers, and make the development of the enterprise go farther and longer.

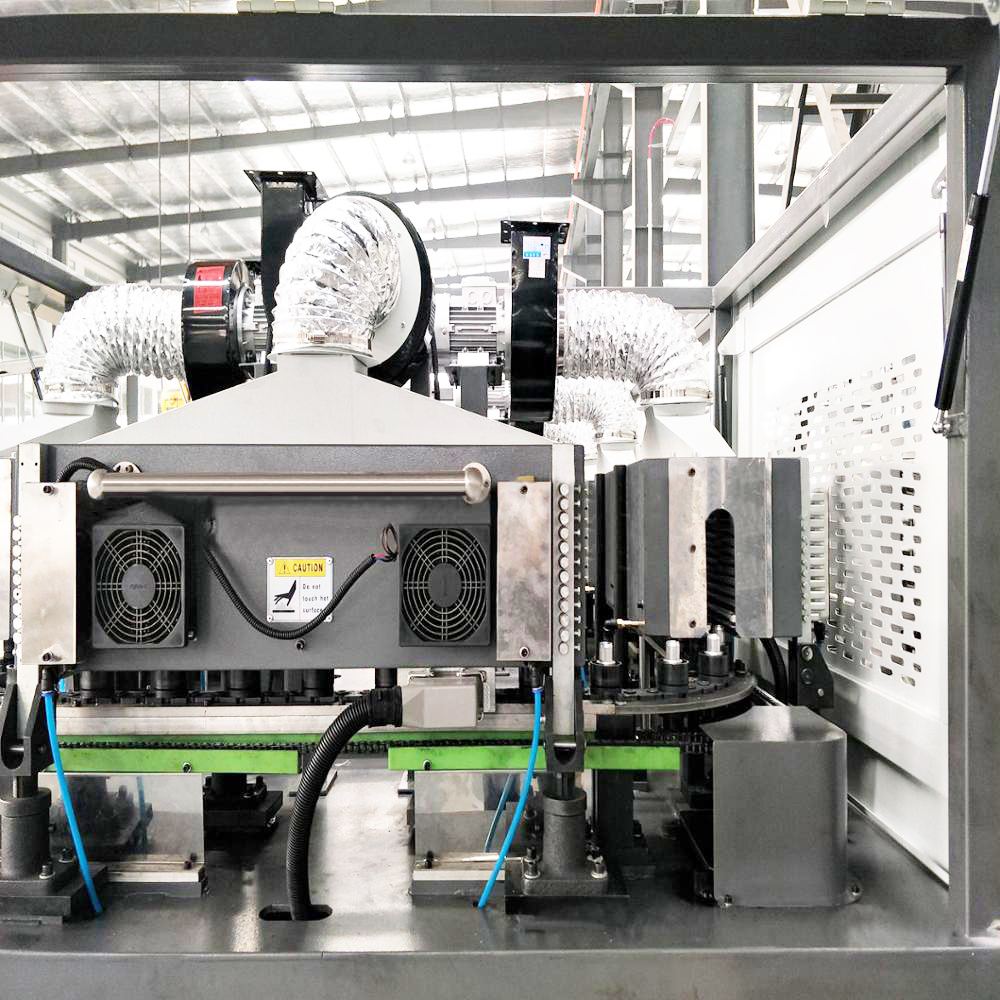

Fully Automatic PET Stretch Blow Molding Machine

Automatic PET stretch blow molding machine is a new generation of automatic PET bottle manufacturing machine for mass production of PET bottles and jars, Ideally suitable for medium and large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower. We offer 4 cavity automatic PET stretch blow molding machine, 6 cavity automatic PET bottle blowing machine and 8 cavity PET stretch blow molding machine. They can blow bottles in shapes such as carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type such as PET and PP etc.

Automatic PET blow molding machine starts as jumble preforms are loaded into the easy to load,extra large capacity bulk hopper, An elevator moves preforms up to a gravity-based sorter, which aligns preforms on a conveyor. Preforms are then aligned and loaded onto a chute, where they are gravity-fed into the preform holders. The preforms move through the heat tunnels, where they are heated to the optimal blowing temperature prior to entering the molds. From the heaters, preforms are loaded into the custom-designed molds where four bottles are blown at a time. A pressurized liquid chiller keeps the mold temperature in a controlled range to ensure that consistently high-quality bottles are blown. Blown bottles are directly transferred to the exit conveyor which can be easily connected to air conveyor. There is no need to use any additional bottle orientating machines.

Model | HZ-5500 |

No of Cavity | Can be customized according to the output capacity |

Output Capacity | Can be customized |

Max Container Volume | 2 L |

Max Neck Diameter | 38mm |

Max Container Diameter | 115 mm |

Max Container Height | 340 mm |

Heating Power | 35 KW |

Operating Low Pressure | 0.8 Mpa |

Blowing Pressure | 3.5 Mpa |