Contact: Manager Ni

Telephone: 13773289099

Address: Building 9, Dehao Manufacturing Valley, Lekun Road, Zhangjiagang City, Jiangsu Province

With high-quality products, professional services, and systematic support, Xinyizhong helps the construction of modern factories in the filling industry,

to grow together with customers, and make the development of the enterprise go farther and longer.

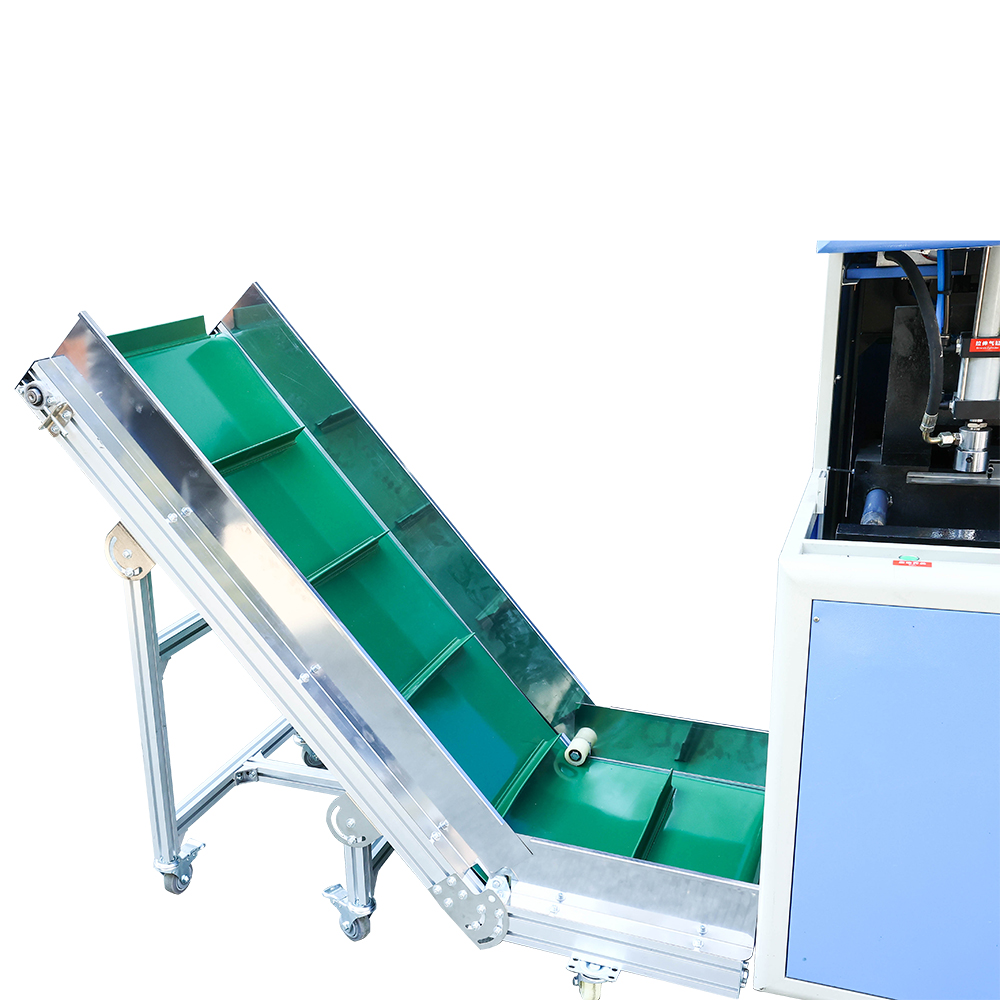

Semi Automatic PET Bottle Blowing Machine

Semi automatic PET bottle blowing machine is the most cost-effective solution for mass production of jars and bottles for small and medium scale factories. The PET bottle making machine is also designed for the production of big jars and containers. Two stage semi automatic PET blow moulding machine is fit to blow carbonated beverage bottles, mineral water bottles, cosmetics bottles and hot-filling bottles. With microcomputer controlling system, it controls various technical parameter needed more accurately and more steadily. It can operate easily without any special training and more safely.

Semi automatic PET bottle blowing machine is ideal solution for mass production of PET bottles for start-up and small-scale companies, and capable of producing a wide variety of high quality PET bottles ranging from 50ml to 6000ml for many industries like bottled water, juice, dairy, liquid detergent, vegetable oil, cosmetics, pharmaceutical and personal care items which are just a few examples. Speed of 800 bottles per hour at 500ml can be achieved, Standard machine includes preheater and blow molding machine, air compressor and air filters are for option.

This plastic bottle blowing machine does not require highly trained operators to produce consistent quality bottles. The bottle making process starts by loading preforms into the preheater. The preheater uses a variable speed track that moves the preforms through a heating tunnel. The heat tunnel has specially designed heating elements for a consistent heating operation with minimal maintenance.

When the preforms have made one trip through the preheater, they are manually loaded two at a time into the blow molder. Operator presses the two mould close buttons to close the mould which is specially designed for safety operation. After the bottles are formed in the blowing cycle, they are removed and the cycle continues.

Key Features

Can operate easily without any special training and safety operation

Original FESTO air cylinder

Minimize your initial investment by starting small

Add additional systems economically as your business grows

Bottles of different sizes can be produced simultaneously to meet your exact requirements

Change over from one size to another can be completed simply and quickly

The tooling costs (molds) are low since the design of the system is simple

Systems can be dedicated to produce particular bottle sizes

A short operator-training period due to the simplicity of the design

Maintenance costs are kept to a minimum and highly-trained personnel are not required

Simple operation does not require highly trained operators

Model | HZ-880 | HZ-880(S) | HZ-880(L) |

Applicable Preform Material | PET/PP | PET/PP | PET/PP |

Bottle Size and Nos of Cavity | 0.05-2.0 L(2-cav); 3-6 L(1-cav) | 0.05-2.0 L(cavity) | 3-6 L(2-cavity) |

Output Capacity | 700-1000 BPH | 700-1000 BPH | 600-800 BPH |

Max Bottle Height | 360 mm | 360 mm | 360 mm |

Max Bottle Diameter | 180 mm | 180 mm | 180 mm |

Max Mould Plate Dimension(LxW) | 420×500 mm | 320×420 mm | 450×620 mm |

Clamping Force | 180 KN | 120 KN | 220 KN |

Power Consumption | 12 kw | 12 kw | 12 kw |

Power Supply | 220~380V/50~60 HZ | 220~380V/50~60HZ | 220~380V/50~60HZ |

Machine Dimension(L x W x H) | 1.66×0.74×2.2 M | 1.2×0.55×1.9 M | 1.7×0.82×2.2 M |

Machine Weight | 700kgs (approx) | 500kgs (approx) | 900kgs (approx) |

Preheater Dimension(L x W x H) | 1.46×0.71×1.58 M | 1.46×0.71×1.58 M | 1.77×0.72×1.58 M |

Preheater Weight | 300 kgs(approx) | 300 kgs(approx) | 500 kgs(approx) |